PRODUCTS

........................................................................

................................................................

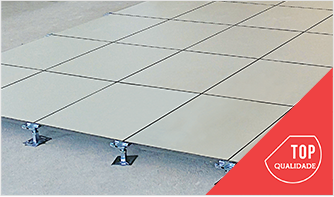

Access floor panel: Cold rolled carbon steel tile with 2mm, SAE 1008 1,90x125, stamped and deep-drawn, with final dimension of 85x85mm. The four-hooked corners provide perfect fixing of the floor panels (stamped with the same frame), discarding the mandatory use of screws.

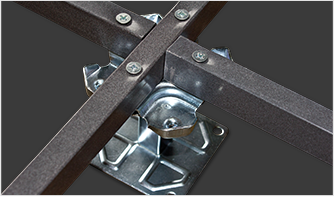

They have on the surface 4 M6X1mm threaded holes for the floor panels fastening, when projected, and 4 M5x0,8mm threaded holes for the stringers fixation, when assembly demands bracing or perimeters limiter setting. Their surface grooves provide the part strengthening and are used as a projection for the further welding to the supporting panel and to the threaded rod.

Supporting panel: Cold rolled carbon steel tile with 1,9mm, SAE 1008 1,90x80, stamped and deep-drawn, with final dimension of 80x80mm. The four-rounded corners, designed for the access floor panel fixing, confer a greater hardness to the set. Their surface grooves provide the part strengthening and are used as a projection for the further welding to the access floor panel.

They have on the centre a stamped hole and a 5mm drawn pipe which enable the threaded pin into and keep it perpendicular to the set. After the connection

with the access floor panel, done by spot weld machine (approx. 100kVA), the four holes from their edges align to the four holes on the access floor panel for the thread M6 screwing.

Threaded pin: Solid carbon steel pin, SAE 1008, with ¾ or ⅝ rolled thread, into the drawn pipe from the supporting panel. It is welded perpendicularly to the access floor panel by spot weld machine (approx. 100kVA). After the thread screwing, it is stamped twice on the bottom to prevent spinning inside the pipe, ensuring the defined levelling.

Nut: 28mm hexagon nut. It is stamped in carbon steel, SAE 1008, ¾ or ⅝ rolled internal thread, and with a total length of 1,5. It has 2 or 4 locks that fit to the squared tube from the base and provide meticulous adjustment with the tile level.